Saving money while investing in advanced manufacturing processes can be challenging, especially when dealing with intricate pieces with numerous materials and colors. However, there is always a way to improve how you manage your expenses.

Plastic injection molding can help your company improve operations and save on extraneous expenses. The cost of plastic injection molding may seem steep upfront, but its long-term benefits ensure an excellent ROI.

This article will dive into cost-cutting tips you can apply to your next project.

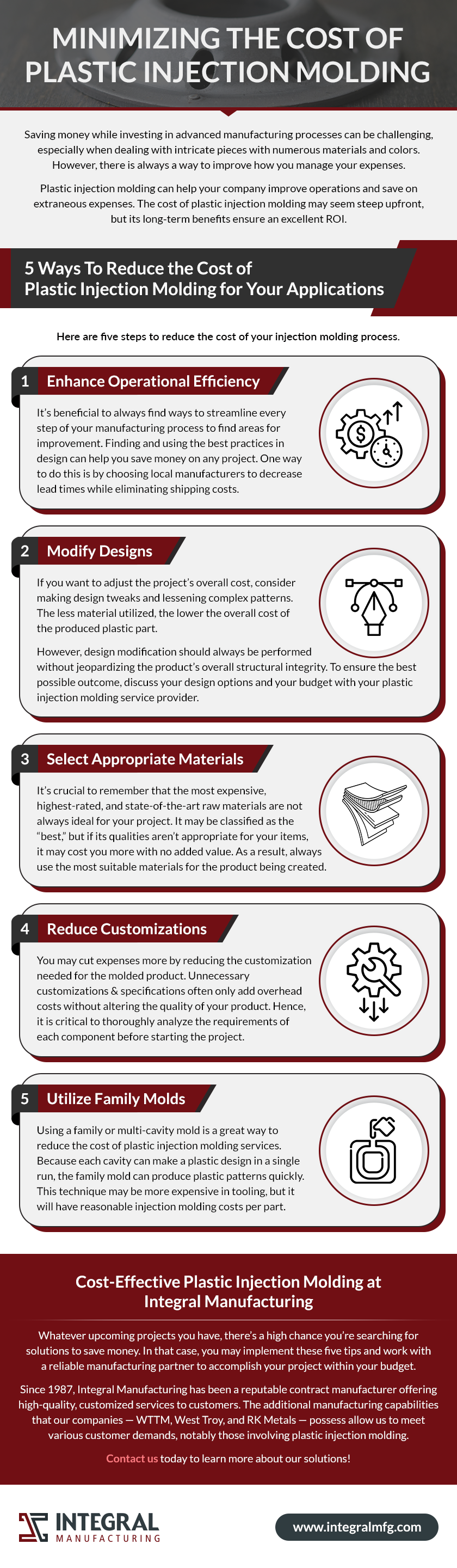

5 Ways To Reduce the Cost of Plastic Injection Molding for Your Applications

Here are five steps to reduce the cost of your injection molding process.

1. Enhance Operational Efficiency

It’s beneficial to always find ways to streamline every step of your manufacturing process to find areas for improvement. Finding and using the best practices in design can help you save money on any project. One way to do this is by choosing local manufacturers to decrease lead times while eliminating shipping costs.

2. Modify Designs

If you want to adjust the project’s overall cost, consider making design tweaks and lessening complex patterns. The less material utilized, the lower the overall cost of the produced plastic part.

However, design modification should always be performed without jeopardizing the product’s overall structural integrity. To ensure the best possible outcome, discuss your design options and your budget with your plastic injection molding service provider.

3. Select Appropriate Materials

It’s crucial to remember that the most expensive, highest-rated, and state-of-the-art raw materials are not always ideal for your project. It may be classified as the “best,” but if its qualities aren’t appropriate for your items, it may cost you more with no added value. As a result, always use the most suitable materials for the product being created.

4. Reduce Customizations

You may cut expenses more by reducing the customization needed for the molded product. Unnecessary customizations and specifications often only add overhead costs without altering the quality of your product. Hence, it is critical to thoroughly analyze the requirements of each component before starting the project.

5. Utilize Family Molds

Using a family or multi-cavity mold is a great way to reduce the cost of plastic injection molding services. Because each cavity can make a plastic design in a single run, the family mold can produce plastic patterns quickly. This technique may be more expensive in tooling, but it will have reasonable injection molding costs per part.

Cost-Effective Plastic Injection Molding at Integral Manufacturing

Whatever upcoming projects you have, there’s a high chance you’re searching for solutions to save money. In that case, you may implement these five tips and work with a reliable manufacturing partner to accomplish your project within your budget.

Since 1987, Integral Manufacturing has been a reputable contract manufacturer offering high-quality, customized services to customers. The additional manufacturing capabilities that our companies — WTTM, West Troy, and RK Metals — possess allow us to meet various customer demands, notably those involving plastic injection molding.

Contact us today to learn more about our solutions!